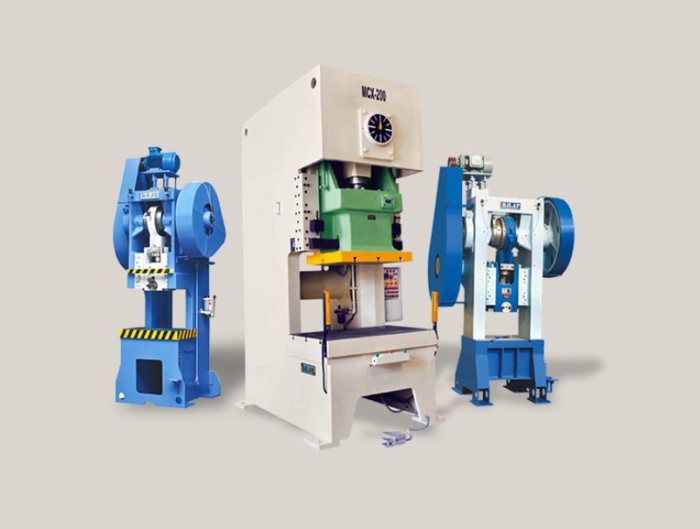

In industrial facilities, having a power press machine is a crucial investment. These machines are imperative for the production process, high efficiency, as well as shaping metal components with precision. After having a machine through reputed power press manufacturers in Ludhiana, it is essential to regularly maintain it for a smooth operation. Overlooking the maintenance part can result in unexpected breakdowns, expensive repairs, and high downtime. This article will help you understand the power press machine’s maintenance tips, which can result in long-lasting equipment and smoothly running processes of factories.

The negative effects of overlooked power press machine maintenance

Without following the necessary maintenance norms, power press machines can face unimaginable problems that can affect their performance, longevity, and reliability. The consequences that can be faced after overlooking the maintenance of these machines are:

-

Decreased efficiency and productivity

A poorly maintained power press machine can offer issues with efficiency and productivity. The factor owners can face worn-out components, limited lubrication, misalignment, etc. All these factors can diminish the speed and production accuracy. Also, there can be production delays and limited customer demand.

-

High risks to the safety of an operator

Poor maintenance of these machines can put operators in life-threatening situations. The malfunctioning components can be scary as they can lead to various accidents or injuries. This is why regular maintenance or inspection is required. The following checks ensure that the machine is in optimal condition, that accidents do not occur, and that employees remain safe.

-

Negative environmental impact

Poorly maintained power press machines can generate noise, vibration, and even emissions, which can create a negative impact on the environment. Also, various pollutants can be released into the environment.

-

High costs of repair and replacement

Ignoring the maintenance plan can result in frequent breakdowns and failure of machinery. Further, it can result in costly repairs, and you might even end up replacing it.

-

Compromised quality of the goods

The quality of products is equal to a good brand reputation. But with neglected maintenance of power press machines, the final product can have inaccuracies, uneven structural integrity, and more scrap. Further, revenue loss, poor product quality, etc. can be faced.

Maintenance tips to follow for power press machines

For the smooth operation and durability of power press machines, it is essential to maintain them. Here are a few effective maintenance tips to follow for power press machines:

-

Undivided attention to cleaning and lubrication

Focusing on the regular cleaning and lubrication of these machines should be an essential task. This can help in getting rid of the debris, dust, as well as metal shavings. Try to use appropriate cleaning agents, which are suggested by the manufacturer, to avoid damage. Ensure that lubrication is done on every moving part to minimise friction, wear and tear, and premature failures. However, this maintenance tip should be followed with a predetermined schedule. Ensure that you are tracking everything for better frequency and effectiveness.

-

Inspection and preventative maintenance

Another tip that can be followed is regular inspections as well as preventative methods for maintenance. This can help in identifying the issues beforehand. Ensure that you have a comprehensive checklist for the inspection of different components, such as electrical systems, clutch, braking, etc. Also, regular maintenance activities of worn-out parts, hydraulic system checks, etc., are done to avoid any unexpected failures.

-

Inculcate employee training

Investing some time in employee training as well as machinery awareness can be helpful with the maintenance practices. This is why it is essential to guide the operators about regular maintenance and how to operate the power press machines. Ensure that this maintenance culture is followed religiously to avoid any abnormalities. Properly trained staff can enhance productivity and help maintain the machinery.

-

Proper alignment and calibration

Alignment, along with calibration, can help with the accuracy. With time, the machinery can lose its proper alignment, and this can hinder its performance. Keeping a check on the alignment and adjusting it can help with the machine’s uniformity and precision. Whereas, calibration can be maintained with regular checking of settings, digital displays, etc., for optimal performance and consistent working of the machine.

-

Collaborate with the power press manufacturer.

A robust relationship with power press manufacturers is essential. The valuable guidance and maintenance practices can be offered by them during the training programs. Also, be in touch for regular updates about new maintenance recommendations, potential upgrades, and much more.

Conclusion

Maintenance is not a mere option in case of power press machines. This is a fundamental requirement for the smooth operation of the machinery. Failing to maintain the machinery can result in poor efficiency, a bad business reputation, safety issues, high maintenance costs, and much more. Thus, prioritising maintenance, maintaining a cleaning schedule, keeping details of everything, and following other maintenance tips can be helpful in many ways. Also, it is essential to be in regular touch with the power press exporter in Ludhiana to enhance your productivity, profitability, reduce machinery issues, and much more. Thus, for the overall industrial facility’s success, power press machines need to be maintained properly.

Leave A Reply